Lightweight Plastic Zipper For Kids’ Clothes, Pouches And Crafts

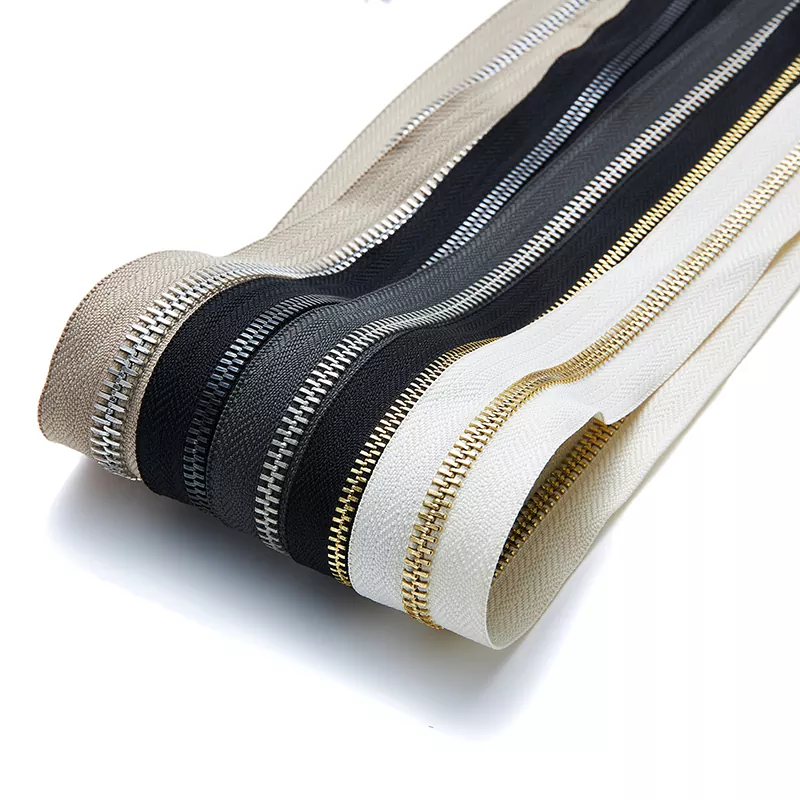

TRC's plastic zipper series, featuring injection-molded plastic teeth, offers a lightweight, robust, and three-dimensional look, making it a widely used zipper type in outdoor apparel, children's clothing, bags, casual wear, and sports equipment. Compared to other types of zippers, plastic zippers have a greater visual presence and therefore offer significant advantages in corrosion resistance, water resistance, and visual appeal. Furthermore,compared to metal zippers, resin zippers are lighter, making them suitable for products emphasizing design or outdoor durability.

This series offers a variety of structural options, including the basic standard plastic zipper, the plastic-coated zipper using an injection molding coating process, special-shaped teeth styles with unique designs, the eco-friendly recycled plastic zipper made from recycled materials, and the waterproof plastic zipper. These products cover a full range of needs, from basic durability to personalized aesthetics and functional upgrades. The different styles each have their own unique characteristics in terms of tooth shape, weather resistance, sustainability, and visual appeal, forming a complementary product matrix that provides more flexible design options for various apparel and equipment.

Compared to other zipper categories such as nylon, metal, and waterproof zippers, plastic zippers prioritize a three-dimensional appearance, corrosion resistance, and medium to high weather resistance, making them ideal for outdoor gear, sportswear, and children's clothing. TRC will leverage its stable injection molding technology, high-quality resin materials, and diverse tooth designs to provide customers with professional plastic zipper solutions that combine functionality with distinctive design.