A tiny revolution that connects life

In modern life, there is a seemingly insignificant yet ubiquitous invention that has profoundly changed our daily lives - the nylon zipper. From suitcases to sportswear, from backpacks to tents, this kind of connecting part composed of plastic threads and metal accessories, with its light weight, durability and low cost, has become an indispensable basic component in global manufacturing. Its birth not only solved many pain points of traditional buttons and buckles, but also continued to evolve in nearly a hundred years of development, becoming a classic example of the combination of industrial design and materials science.

I. From Metal to Nylon: The Material Revolution of Zippers

The prototype of the zipper can be traced back to the end of the 19th century. However, early products were mostly made of metal, which had the disadvantages of being heavy, prone to rust and high cost. It was not until the 1930s, when DuPont of the United States invented nylon material, that the zipper manufacturing industry witnessed a breakthrough transformation. In 1940, the Japanese YKK Company was the first to achieve industrial production of nylon zippers. By heating and melting nylon resin, extruding it into filaments, and then weaving them into chain straps, and combining them with metal or plastic pull pulls, it created the first lightweight zipper product.

The application of nylon material has completely transformed the properties of zippers: compared with metal zippers, nylon zippers are 40% lighter, their corrosion resistance has been enhanced to withstand a 500-hour salt spray test, and their production costs have been reduced by nearly two-thirds. During World War II, nylon zippers rapidly gained popularity due to their adaptability to the lightweight requirements of military clothing. The US military alone purchased over 100 million nylon zippers for uniform production. This period is also known in the industry as the "war dividend period of zippers".

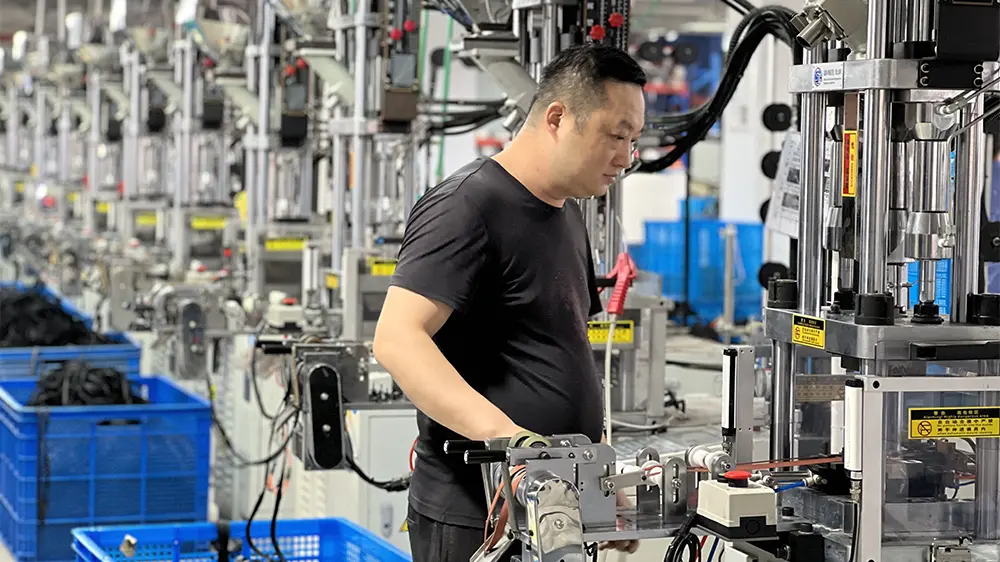

Ii. Precision Manufacturing: The Production Code of Nylon Zippers

A qualified nylon zipper needs to go through 12 core processes, and its manufacturing precision is comparable to that of precision instruments. Firstly, in the production of nylon filament, by controlling the temperature of the extruder (usually between 250 and 280℃) and the traction speed, it is ensured that the diameter error of each nylon monofilament does not exceed 0.02mm. Then comes the chain belt weaving stage. A special double-needle bed warp knitting machine is used to weave the nylon filament into a base belt with uniform tooth holes. The tooth hole spacing needs to be maintained within an accurate range of 0.8-1.2mm.

The most crucial process is injection molding. A high-speed injection molding machine is used to inject molten nylon resin into the chain belt tooth holes, which are instantly cooled to form zipper teeth. This step requires precise control of the injection pressure (typically 80-120 mpa) and cooling time (0.8-1.2 seconds) to ensure the strength and consistency of the zipper teeth. Finally, after assembling the pull tabs, top and bottom stops and other accessories, and passing the tensile test (standard nylon zippers need to withstand a lateral tensile force of ≥200N), they can become qualified products.

Iii. Scene Empowerment: Penetrating Every aspect of Life

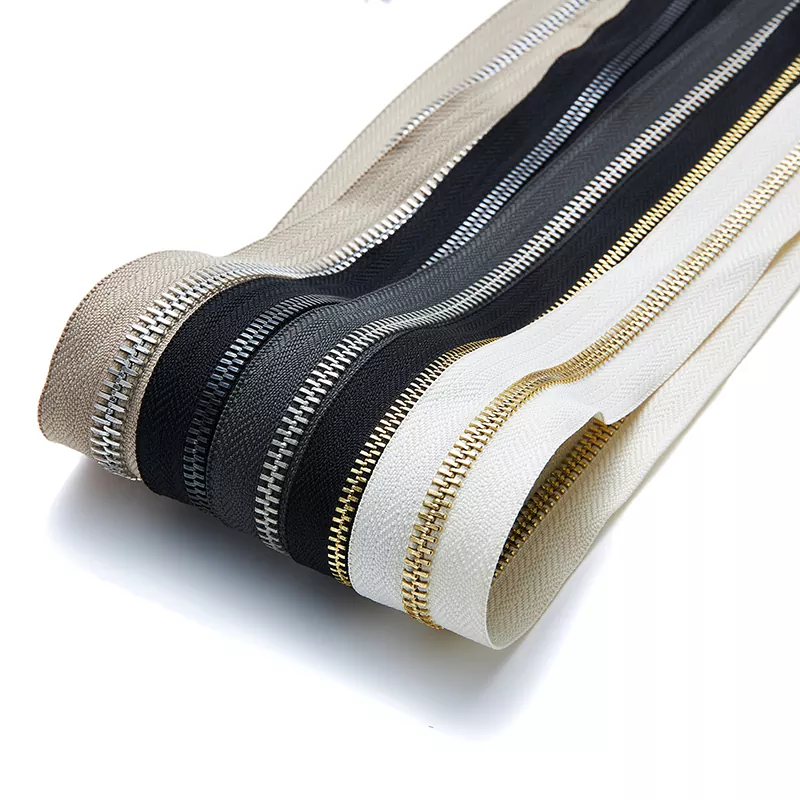

Nylon zippers, with their excellent cost performance, have become the preferred connectors in many fields. In the field of clothing, thin and light nylon zippers are widely used in sportswear and down jackets. Their soft nature can prevent skin friction. The waterproof nylon zipper achieves IPX5 water resistance by applying a TPU coating on the surface of the chain strap, making it a standard feature for outdoor raincoats.

In the field of luggage, the thickened nylon zipper (with a chain tooth diameter of ≥1.5mm) can withstand frequent opening and closing. Combined with the anti-theft pull design, it becomes a safety guarantee for suitcases. The invisible nylon zipper, by concealing the chain strap in the fabric interlayer, provides a simple and elegant appearance for high-end handbags.

In the industrial field, high-temperature resistant nylon zippers (capable of withstanding temperatures up to 150℃) are used in automotive seat covers and industrial protective clothing. Flame-retardant nylon zippers meet the safety requirements of public places such as subway seats and aircraft interiors by adding flame retardants. According to statistics, over 50 billion nylon zippers are produced globally each year, with an average of more than 7 per person used annually.

Iv. Future Trends: Continuous Evolution Driven by Technology

With the development of materials science and intelligent manufacturing, nylon zippers are moving towards a more functional and environmentally friendly direction. In terms of material innovation, the bio-based nylon zipper uses PA56 material made from fermented corn starch, which reduces carbon emissions by 30% compared to traditional nylon and has begun to be applied in fast fashion brands. Graphene-modified nylon zippers, by adding graphene powder, endow the zippers with antibacterial and conductive functions and can be used in smart clothing.

In terms of process upgrading, 3D printing technology can achieve personalized zipper tooth design, meeting customized demands. The automated inspection system, through machine vision technology, has raised the inspection accuracy of zippers to 0.01mm, significantly enhancing production efficiency. In the future, with the integration of Internet of Things (iot) technology, smart nylon zippers equipped with RFID chips may become new carriers for product traceability and anti-counterfeiting.

From solving the cumbersome task of buttoning up clothes to becoming a tiny unit of intelligent manufacturing, the development history of nylon zippers can be regarded as a typical case of "small inventions changing the big world". This seemingly simple connecting component not only embodies the advancement of materials science but also reflects the continuous optimization of the quality of life by industrial design. In the future, with the in-depth development of green manufacturing and intelligent technologies, nylon zippers will continue to connect more convenient, environmentally friendly and intelligent lifestyles in their tiny forms.

-