FAQ

We are a manufacturer! We set up in 2004 by 21 years working on zipper indurstry.

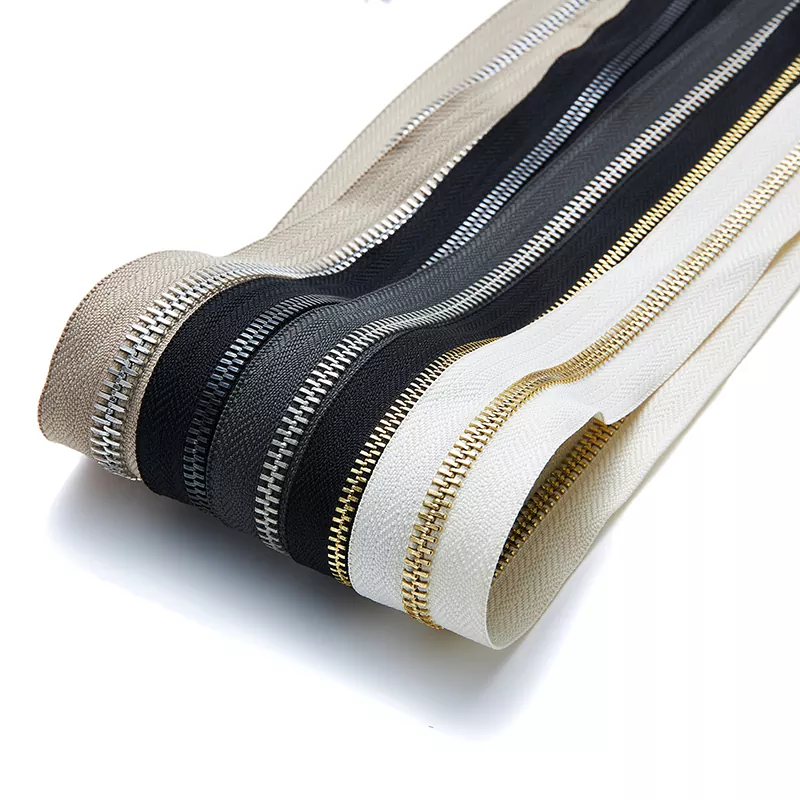

Our main products include: all kinds of zippers and zipper sliders, such as interlocking zipper, invisible explosion-proof zipper, metal zippers, nylon zippers, resin zippers of 3#5#,7#,8#,10#type.

TRC interlocking zippers combine premium nylon tape with robust polyester teeth, delivering both durability and smooth operation. Their unique design allows effortless connection of any two zippers of the same model (regardless of colour or batch), offering users a flexible and convenient experience.

TRC invisible explosion-proof zippers offer two types of tape options: standard fabric tape and lace fabric tape. This product boasts a reverse fold strength exceeding 110N, far surpassing the standards of leading international brands. It ensures smooth and reliable operation even under high-frequency use and strong pulling forces.

Industry Experience: With 21 years of specialised expertise in zipper manufacturing, we swiftly comprehend client requirements and deliver tailored solutions.

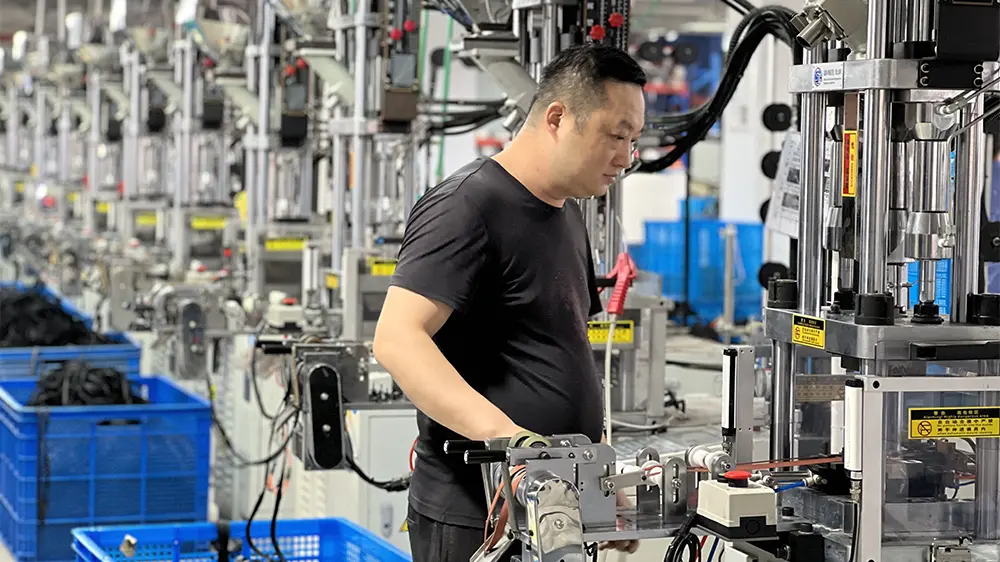

Superior Quality: Utilising reliable raw materials and rigorous quality control processes, we ensure every zipper exhibits exceptional durability.

Smart Manufacturing: Equipped with modern production facilities and masterful craftsmanship, we guarantee product stability and consistency.

Continuous Innovation: We remain committed to product innovation, continually developing new materials and designs to provide clients with more competitive and differentiated zipper solutions.

End-to-End Service: Delivering comprehensive solutions from R&D and prototyping through production to after-sales support.

Reliable Supply: Ample production capacity and stock levels guarantee consistent fulfilment of large-scale orders.

Environmental Responsibility: Committed to green manufacturing practices using eco-friendly materials to support sustainable development.

Long-Term Assurance: A robust after-sales system ensures customers enjoy complete peace of mind.

Yes, but you have to pay to get samples and shipping fee also will be charged.

Yes. We can open mould by following your requirements, but kindly note that customization may require additional fees.

Yes, we can. We have our own factory and we welcome to customized order by following your requirements, including customized sliders/pullers/teeth, teeth colors, tapes with mixed colors, textures, etc. Kindly note that customization may require additional fees.

After you receive and confirm the samples, our sales team will issue a proforma invoice. We require a 30% deposit to begin production, with the balance payable before shipment. Other payment terms may be available for long-term customers with established credit. We also warmly welcome you to visit our factory for evaluation before placing orders.

Sample-time is 5-7days, the bulk- production is 7-15 days. Something is in a hurry when to produce your order and you wanna speed up order’ s process, we will postively communicate with you to fix it and meet your requirements.

We accpet multiful-payment methods. How to pay depends on the communication between us.

For our stock, the package method is OPP/PE bag inside then by carton outside. And we can also customize packageing accessories according to your requirements. If you are not sure the denification’ s packaging requirements, please feel free to contact with us, we will keep patient to communicate with you.

As usual, most of order’ s delivery dates are between 10-20 days after confirming everything. For your delivery date, if something happened suddenly in a hurry, the factory is our own, we can positively communicate with you right away to fix the problem and change production time for you.

Zipper Knowledge

TRC has researched and developed materials, surface treatments, strengths, and zipper designs to prevent false needle detection.

Generally speaking, the color fastness reaches Grade 4 for most colors and Grade 3.5 for some special colors, for example, bright red. However, dye transfer would occur as a result of the chemical reaction that will easily take place between the dispersed dye molecules in the zipper tapes and the plasticizer, adhesive agent, oiling agent contained in such fabrics as vinyl chloride that contains DOP, synthetic leather or fabrics whose surface is coated with resin. Hence, a piece of lining cloth shall be used for separating the fabric from the zipper when sewing is performed and the products in custody or storage should be separated from each other using the leatheroid.

Please confirm with our sales persons when you place an order. We can decrease the chances of dye transfer by improving the color fastness. Please note this might result in greater color difference. Additionally, a piece of lining cloth shall be used for separating the zipper from the fabric when sewing is performed.

In the clothing production process is mixed iron metal parts which likely needle or pin. The use of iron objects containing objects through the electromagnetic field changes in the principle of the needle detector, you can easily check the clothing is mixed with stitches, pins and other iron metal, to avoid harm to the human body.